Flanges are essential for connecting pipes and enabling the flow of liquids and gases in many industrial applications. For your system to be of the highest caliber, last the longest, and function at its peak, selecting the appropriate flange source and manufacturer is crucial. Mcneil Instruments Inc. stands itself as a reputable supplier of flanges and other steel products in this area.

Mcneil Instruments Inc. is a reputable manufacturer, exporter, and stockist of flanges in a range of materials and requirements, thanks to its 37+ years of experience and dedication to perfection. In order to meet the requirements of various applications, the company offers a wide selection of flanges made of materials such as alloy steel, carbon steel, and stainless steel.

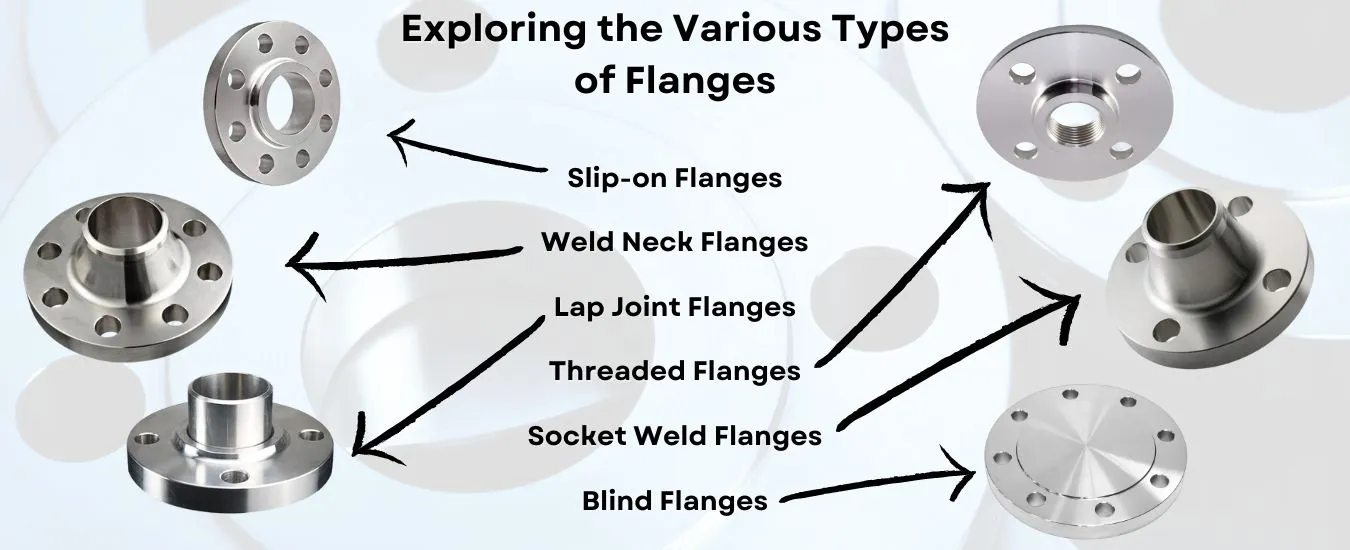

Slip-on Flanges:

The slip-on flange is a straightforward and excellent solution for a weld neck because it requires a weld bevel and enables the pipe’s length to be modified in relation to the flange’s placement. In order to weld around the pipe’s outside diameter (OD) and on the interior side of the connection, slip-on flanges are a common type of pipe flange that may accept pipe into the bore or center of the flange.

Weld Neck Flanges:

Weld neck flanges are utilized in applications where the conditions are major and vital. Some of these situations include high levels of pressure, significant temperature and pressure swings, high temperatures, flammable and dangerous fluids, and extremely low temperatures. The purpose of this kind of flange is to buttweld superior and comparatively natural-form connections to pipes. This kind of flange connection is almost always used for larger diameters and higher pressure classifications.

Lap Joint Flanges:

Lap joint flanges have an extended hub and a machining radius at the bottom of the flat face. They are a less popular type of flange. His curved radius enables the installation of a stub end, a type of pipe fitting. This kind of flange is designed to rotate over stub-end fittings. The pair is a great option for circumstances where the connection needs to be constantly removed and reinstalled for inspection. With this setup, it is possible to accurately bolt the lap joint over the stub end.

Threaded Flanges:

The center of threaded flanges, also known as companion flanges, screw flanges, or NPT flanges, has a female NPT thread for attaching to male NPT threaded piping. Creating reduction connections frequently involves using threaded flanges. The most common threaded flange sizes are 1/2 inch to 6-inch nominal pipe sizes; however, if needed, we can provide NPT threaded flanges up to 24 inches.

Socket Weld Flanges:

For flanges that need less overall space than a standard weld neck flange, socket weld flanges are a less popular but equally effective connection. They have a counter bore in the center to enable a clean weld of pipe into the socket. When necessary, these are a great replacement for weld necks and slide-ons because they are typically provided in smaller nominal pipe sizes.

Blind Flanges:

A blind flange is a piece of solid steel that has no inner diameter or bore and is primarily used to close off a line. Blinds provide the ends of pipe connections with a well-formed termination point or allow the media in issue to be redirected towards another part of the pipe assembly, whereas the majority of flange connections permit the passage of air or fluid via an interior opening.

Conclusion:

The ability of Mcneil Instrument Inc. to manufacture unique flanges that adhere to strict customer specifications is one of its primary advantages. No matter what size, thickness, or material you require your flanges to be, the company has the know-how to meet your requirements. Your flanges will be properly suited to your unique system and application thanks to this level of customization.

Mcneil Instrument Inc. is renowned for its great customer service in addition to its high-quality flanges. The company’s staff of professionals is ready to help you with all facets of your flange requirements, from choosing the best product to making sure it is delivered on time and at the appropriate price. Mcneil Instruments Inc. can assist you whether you need to replace worn-out or broken parts or are searching for a trustworthy flange supplier for a new project.